Customers Routinely See...

10-15%

Customer Satisfaction

100%

Realtime Visibilty

30-35%

Asset Utilisation

50-60%

Billing Cycle

30-35%

Manual Labor

15-20%

CO2 Emissions

15-30%

Driven Miles

nuVizz TMS Multi-Leg Transporation Visibility

Actionable intelligence to manage and grow your business

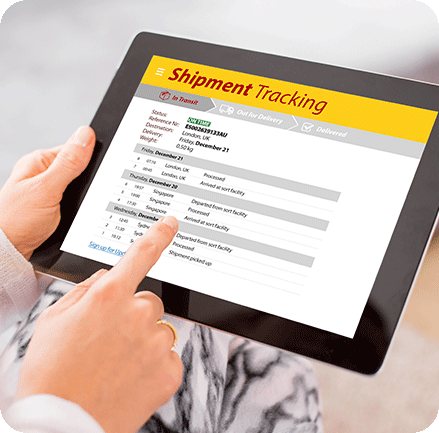

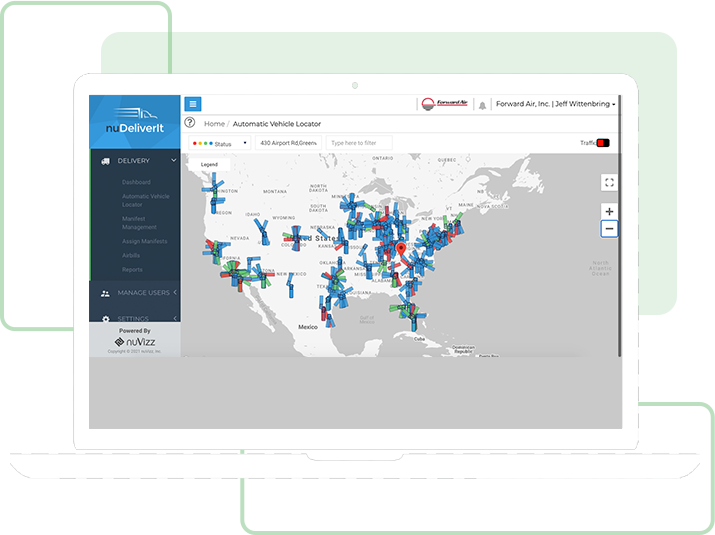

Real Time Visibility of Network Wide Cross Docking

nuVizz TMS enables real time tracking of events across several cross docking facilities throughout the entire network involving multiple delivery entities like your private fleet, carrier/agents, outsourced delivery partners, crowd resources etc.

Cost Reduction Through Efficient Cross Dock Operations

Accurate planning of shipment legs through multiple hubs ensures swift and timely movement of consignments reducing costs incurred due to longer detention at hub yards and dock doors. Barcode based driver scanning capability ensures pick up and delivery accuracy reducing any penalties for inaccurate deliveries.

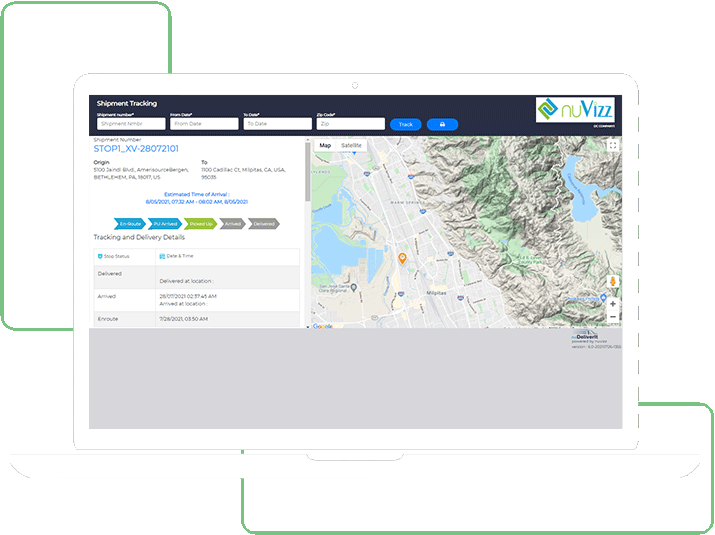

Better Customer Experience with Improved Cross Docking

Reduce call center requirements and delight customers by providing accurate and real-time context-sensitive visibility information across pool distribution points.

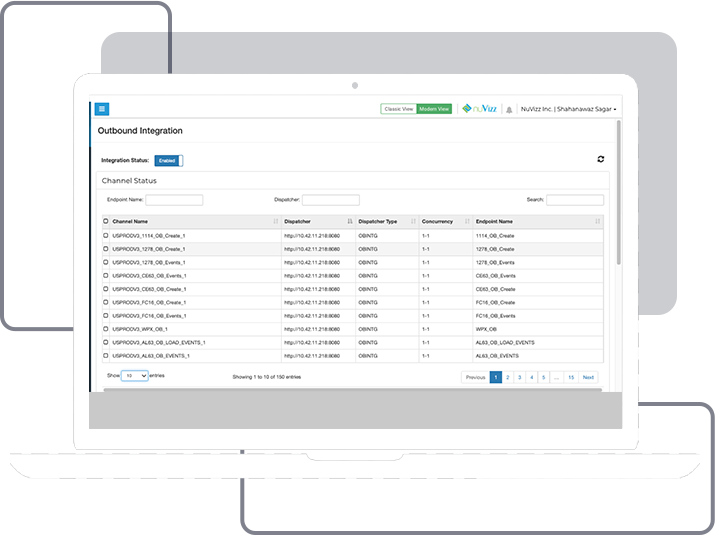

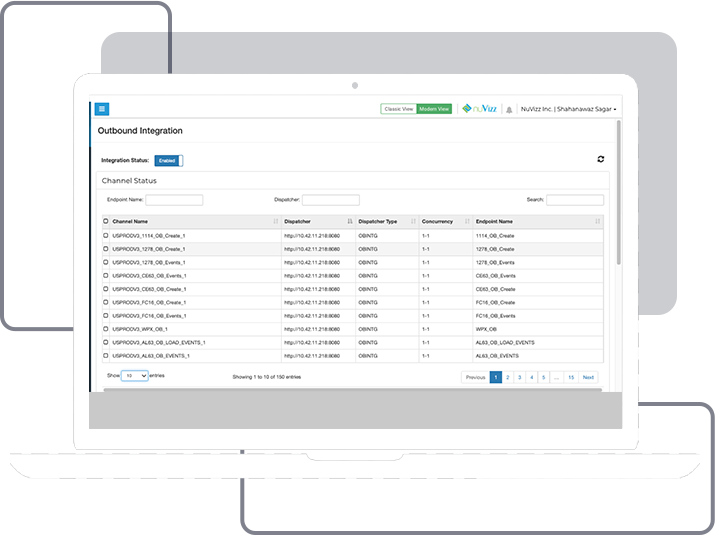

Event Based Exchange of Information Across Pool Distribution Points

nuVizz TMS automates the many-to-many integrations with your delivery partners across all cross docking facilities, both up and down the supply chain to improve collaboration and eliminates the need for point-to-point integration.

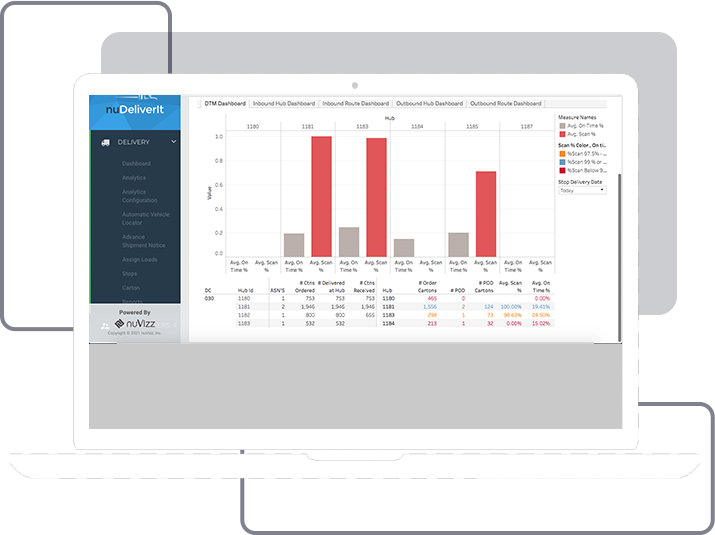

Proactively Monitor and Manage Exceptions

Manage by exceptions. Platform helps to create automated workflow configurations to monitor as well as take actions.

Actionable Business KPIs of All your Port Moves

Real-time visibility is not just data but it is actionable business metrics and KPIs across your delivery network including every cross docking facility or pool distribution hubs without missing a single port move.

Multi Leg Distribution - Enterprise Ready

A valuable transportation model, that can hugely benefit from advanced planning for Terminal labour needs, ETA and transportation planning. The oversized benefits from the platform approach.

Classified as tendered load with multiple stops for delivery. Exceeding expectations with SLA for on-time and accurate deliveries is just a routine matter.

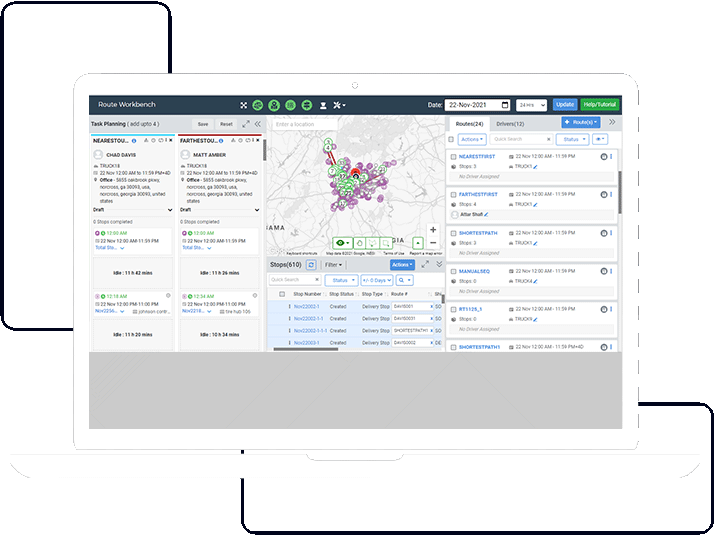

Vehicle Routing and Scheduling for every mile ensuring communication with all stake holders is today a business necessity and not a luxury. Visibility provides ease of planning and execution

Increase efficiency with Centralized Routing and Planning - turn this from a business challenge to a business advantage

The large enterprise delivery network is complex. The partner ecosystem is ever changing with varying requirements. You need a platform that inherently understands this complexity and built with network view in mind.

Expanding or changing your network should be a breeze both for you and your new partners. Fastest network wide deployments? Done that

Customers

000

M

000

+

000

+

000

%

Highlighted Customer Review

Awards

Testimonials

Videos

Blogs

The Ultimate Guide to Logistics Management...

In the rapidly evolving landscape of global trade, logistics management plays a pivotal role. Efficient logistics management ensures that goods are transported, stored, and delivered...

Read More

Enhancing Delivery Efficiency with Dynamic Route...

Efficiency is crucial in the quick-paced world of delivery and logistics. A company’s ability to deliver items precisely and on time can make or break...

Read More

Why Your Business Needs Advanced Delivery...

In today’s fast-paced market, businesses must adapt to the ever-evolving demands of customers. One crucial adaptation is the integration of advanced delivery logistics software. This...

Read More

Press Releases

nuVizz Recognized in the...

ATLANTA, July 10, 2024 (GLOBE NEWSWIRE) — nuVizz, a leading provider of transportation management solutions and...

Read Article

nuVizz Leads the Way...

ATLANTA, Feb. 05, 2024 (GLOBE NEWSWIRE) — nuVizz, a leading provider of transportation management solutions...

Read Article

nuVizz RoboDispatch Solution Recognized...

ATLANTA, Dec. 13, 2023 (GLOBE NEWSWIRE) — nuVizz, a prominent provider of network-based last mile delivery,...

Read Article

FAQs

Cross-dock distribution is a logistics technique that involves unloading incoming items from arriving vehicles, sorting them, and then loading them straight onto outgoing vehicles for prompt delivery. This technique reduces storage space requirements and promotes effective order fulfillment.

When items are received from suppliers, they are quickly sorted and loaded into vehicles headed outward for direct distribution, with little to no storage, in a facility known as a cross-dock. It emphasizes the swift consolidation and movement of goods.

Contrarily, a distribution center acts as a single place for the receipt, storage, and management of inventories. It consists of activities including order fulfillment, inventory management, and value-added services. Longer-term storage of products at distribution centers allows for effective inventory management and order processing.

Using a cross-dock for distribution improves efficiency by reducing handling and storage costs, minimizing inventory levels, and enabling faster order fulfillment.

There are many difficulties involved in operating a cross-dock distribution operation. The management of various product flows effectively, ensuring accurate labeling and documentation, handling potential transportation disruptions, keeping open lines of communication with suppliers and clients, and adjusting to shifting demand patterns are a few examples. A smooth operation also requires a well-designed warehouse, skilled labor, cutting-edge technology, and efficient inventory management.

Numerous capabilities on the nuVizz platform can improve the effectiveness of a cross-dock distribution operation. It offers real-time visibility into shipments, allowing for better inbound and outbound flow coordination. Processes like labeling and documentation are automated by the software, which lowers manual errors. It provides cutting-edge analytics to improve inventory management, labor allocation, and warehouse layout. It enables smooth collaboration with suppliers and customers with the use of communication technologies. The platform's intelligent routing features support efficient management of disturbances to the transportation system. Overall, nuVizz improves decision-making, productivity, and operational efficiency for cross-dock distribution operations.